Regulatory /Contract Requirements Definition

Commercial electronics products need to have the right kind of regulatory compliance markings before they can be offered for sale to the US market and before they can be offered to Europe or Worldwide. We can help you wade through the myriad of regulations, standards, markings and test methods needed for you to successfully market your product – at home or abroad.

Systems integrators have to take numerous RF environments into account when preparing top level requirements that ultimately have to flow to subcontractors. Legal, Inter-system, Intra-system and natural environments all must be considered before a meaningful specification can be produced. We have experience working with systems integrators to generate clear and accurate specifications.

Military and Aerospace subcontractors are sometimes faced with top level requirements that are often confusing or non-standard. These requirements may lead to costly product redesign if not properly managed. We flow top level specifications into solid requirements.

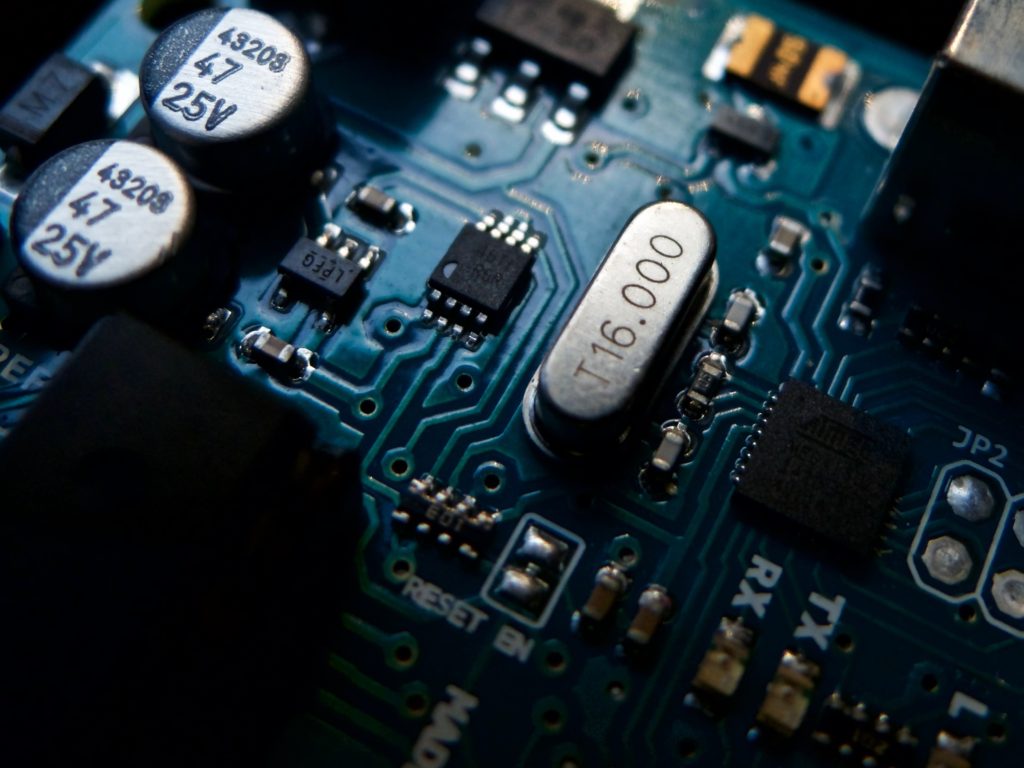

EMI/EMC Design

- Interface and power line filters

- Grounding, bonding and shielding

- Chassis design

- Circuit board layout

- Transient suppression

Customer Liaison

We will represent your company and product to your customers, in working groups, design reviews, EMCABs or other critical meetings. We have the professionalism and confidence needed to take the job seriously and to provide your customer the assurance that their needs are being met.

EMI/EMC Analysis

- SPICE Circuit modeling

- Shielding analysis

- Field to wire

- RF system EMC (intermod, harmonics, spurious response/emissions)

- Self Compatibility

EMI Troubleshooting

Nothing is more frustrating than being under schedule pressure with a design failing EMI in the lab!

We have the experience needed to resolve EMI problems quickly, cost-effectively and with the least design impact to your product. We provide “out-of-the-box” thinking that will lead to a rapid overall solution.

- Pre-test EMI design review to mitigate failures prior to testing

- Engineering level testing and troubleshooting

- Troubleshooting while in the lab

- Post-test data analysis and design recommendations

Test Support

We will act as your company’s representative in the test lab, watching out for your best interests. Product EMI testing is where up-front design and analysis pays off. However, a poor test can lead to false results, either introducing unneeded costs to mitigate false positives or to allow problems to go uncovered, exposing your company to possible contractual or legal risk. We have the experience needed to manage you product’s test accurately and efficiently.

Test Labs range widely in capability, cost and experience. Proper lab selection often balances cost versus risk. We have worked with a number of labs in the past and have learned the lessons of what makes a lab right for a particular product line.

- Test Planning

- Lab Selection

- Lab Scheduling/Coordination

- Witnessing

- Test Reporting

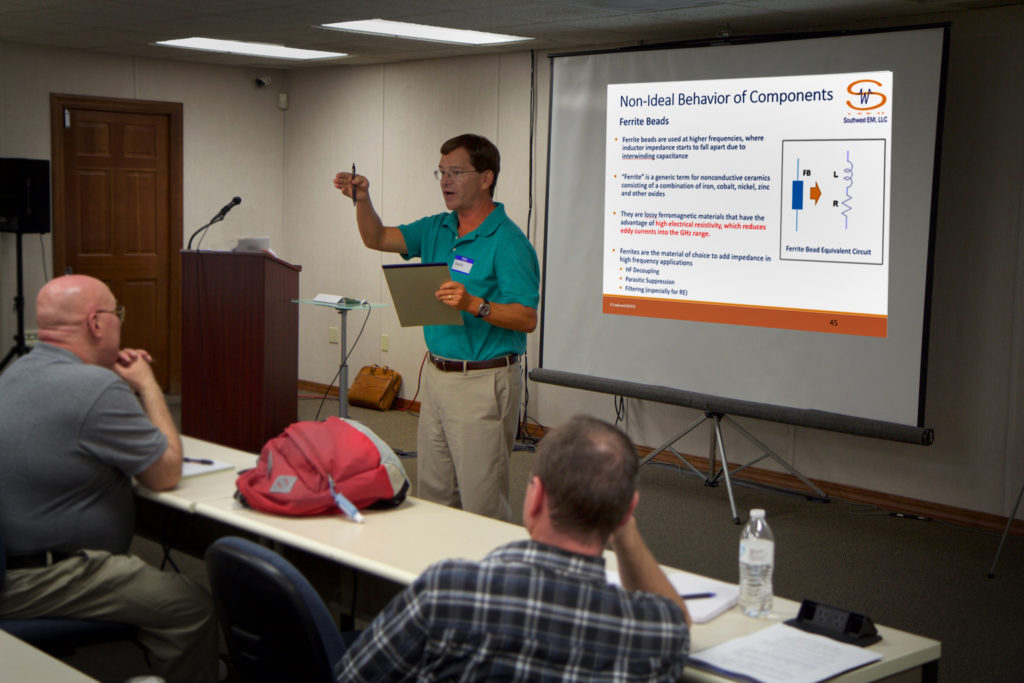

EMI/EMC Training

Companies often do not have a dedicated EMI engineer on staff, and the responsibility for your product’s EMI compliance often falls on engineers from a variety of disciplines. We provide a customized in-house training program focused on your company’s unique EMI requirements, design and test needs. We make it a point to work with your staff to design products that pass the first time – reducing lab costs, product risk and ultimately your time to market.

- Custom Training Modules

- 1/2 day to multi-day course options

- In-house at your facility or at a local lab

- Product specific EMI requirements, electrical and mechanical design, pretesting and final testing.

- “Take Home” training material

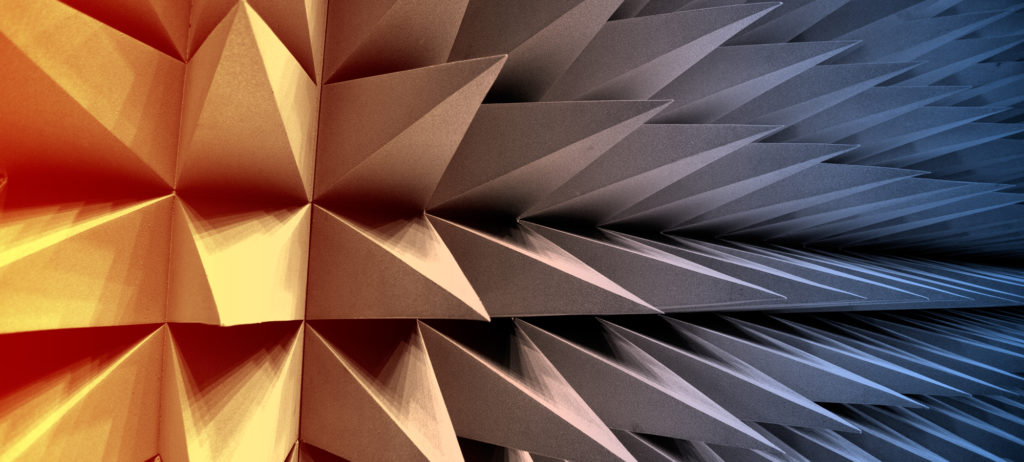

Test Facility Design

We have the background needed to help a client develop test facilities – from engineering a single test method to designing an entire lab. We can work with building architects, test equipment suppliers and chamber vendors to create a solution that will meet your test facility needs in an effective and cost efficient manner.

Schedule a Consultation

Call or Email for an EMI Consultation

Your First Consult is Free!